|

Our Projects Currently in

Progress |

|

On both of these projects,

our role included coordination between multiple

consultants and contractors. We'll help

you turn your project into success no matter how

complicated it is. |

|

|

|

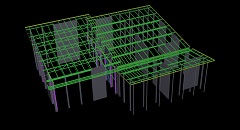

Alloa PS and Reservoir |

|

During construction of

the new pumping station

and reservoir for the

Region of Peel, PROF&E

was hired by Romag

Contracting to design a

steel roof for the

pumping station as an

alternative to the

precast concrete roof, because

the precast option could

not be procured in

Canada. Our project team

worked with the

contractor, the owner, prime

consultant and steel

fabricator to obtain all

necessary permits and

approvals prior to

fabrication of steel.

Some structural steel

components have been

delivered to site, some

are being fabricated and

some are out for

galvanizing. |

|

|

|

East

Marina Development |

|

After

acquisition of the

property and completion

of the planning stage,

PROF&E was hired by the

developer to review

existing sewer

collection system and

design a new system that

is

supposed to accommodate

significantly larger

flows from the proposed

3 multi-story

residential buildings.

The proposed systems

consisted on new gravity

sewer, new sewage

pumping station (with

standby power facility)

and a new force main.

In order to coordinate

sewage system with the rest of

new development, our

work was divided in

two stages: predesign and final

design. |

|

|

|

|

|

|